DIE HEATERS

Home > Products > DIE HEATERS

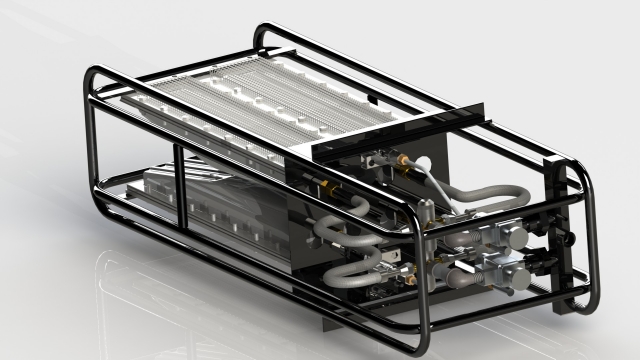

Dy-Kast Supply is the only distributor for the Aitken Infrared Electric Die Heaters. 14 standard size Heaters are available using 240, 480, 550 voltage. All heaters are 3 phase and range from 1500 - 2500 element wattage. The heaters may be operated independently or grouped together on larger dies.

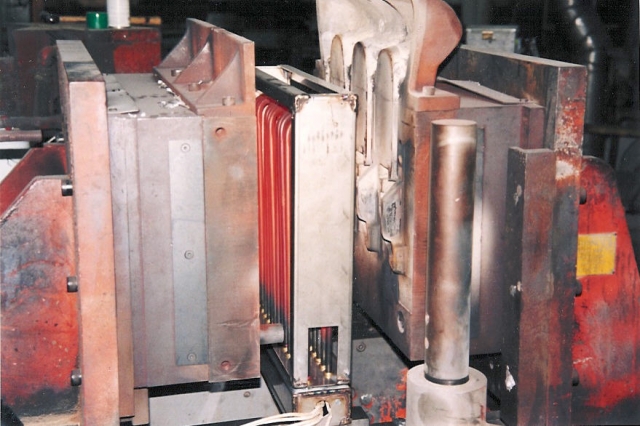

GET A PRE-HEATED DIE AT SHIFT START. The die heater can be installed in the die after shut-down and programmed to start heating prior to the start of the first shift. This allows production to begin at the start of the shift without costly waiting for die warm-up.

MAINTAIN DIE HEAT DURING PRODUCTION BREAKS. Eliminates the need for turning water lines on and off. Just insert the heater in the machine with the dies wide open and you will have enough heat to maintain the desired die temperature.

ELIMINATE SCRAP AT START-UP. Many of our customers are producing good castings immediately after starting operations, accomplished only by using the Aitken Die Heater.

REDUCED DIE MAINTENANCE AND INCREASED DIE LIFE. By preheating the dies, you reduce the differential between operating and room temperature. A reduced temperature difference causes reduced thermal shock and strain on the tooling, which leads to die checking. Hence, the lower the thermal shock, the lower the die maintenance and the greater the service life. DIE LIFE may be extended as much as 300%.

EVEN DIE TEMPERATURES. Some methods of die pre-heating result in extreme unevenness in die temperature. On an average die, these extremes could range from relatively cool spots to burned core pins and annealed sections. Using an Aitken infrared die heater, the die temperature will vary approximately 10 degrees farenheit per inch of distance from the unit. Hence, a die cavity four inches deep would be only 40 deg F. lower in tempareture than the die surface.

FASTER DIE WARM-UP. Many die sections can be pre-heated in a machine to temperatures of 325 deg F. within one hour. For example, we are currently heating a 24" x 48" x 10" two cavity die on a 1000 ton Lester machine. At the end of one hour, we are attaining 315 deg F. using two 13.5 KW heaters, on for each die cavity.

NO BURNED CORE PINS OR HOSES. The electric heating element has a maximum surface temperature of 1550 deg F. Should the element come in contact with a core pin, there would not be enough BTUs at the point of contact to cause any harm.

CLEAN HEAT. With the Aitken Electric heater, there are no by-products of combustion such as carbon which must be removed from the die surface before operation.

Call us at 440-937-7979 or email us at sales@dykast.com.

View Shopping Cart »

View Shopping Cart »